- What Is CE Marking?

- Meeting EU Requirements and Conforming to Directives

- Comparison of Real and Fake CE Marking

What Is CE Marking?

The letters “CE” are the abbreviation of French words “Conformité Européene” which literally means “European Conformity“.

A CE mark is a symbol that must be placed to all products before they can be sold within the European market. The mark shows that a product:

- meets the requirements of relevant European product directives.

- meets all the requirements of the relevant recognized European harmonized performance and safety standards.

- fits for its purpose and will not put in danger any lives or property.

The manufacturer with implementation of CE marking assures that appropriate technical documentation supporting the use of the mark is available and can be provided upon request. Also by the importer or responsible person for its placing on the market.

On the other side CE marking does not provide any specific information to the consumer. It is not a quality assurance declaration, it does not show evidence of third-party testing.

Meeting EU Requirements and Conforming to Directives

Placing a CE mark to a product is taken as meaning of conformance for authorities within the EU member states that the product meets all appropriate EU requirements. There is an EU requirement that products which are not in conformity with the provisions of the directives are not allowed to circulate in the EU countries and there should be taken an appropriate action to remove these products from sale and use within the specific state. One example is the import of toys from China to the UK which, when examined, were found to contain a high level of poisonous toxins that endanger life.

The importer and/or manufacturer must take steps to conform with safety requirements, produce the appropriate records and documentation and decide on the necessary procedures to maintain production in conformity with directives.

In case when there are more han one CE marking directive concerns to a product and a transitional period allows the manufacturer a choice of which to apply, the marking indicates conformity only with those directives applied by the manufacturer. In this case the directives that have been applied must be identified in the documents or notices accompanying the product. Where the manufacturer does not list those directives that have been applied, the authorities will assume that a declaration of conformity is available for all applicable directives.

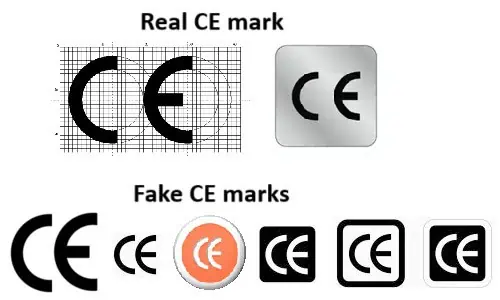

Comparison of Real and Fake CE Marking

Many times happens that some manufacturers do not meet all requirements of EU directives and on the product place fake CE marking.

The top image shows the real CE mark while the lower image shows examples of fake ones.

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

Conclusion

CE marking is a passport to the European market, signaling that a product complies with all applicable EU directives and harmonized safety standards. It places clear responsibility on manufacturers and importers to maintain technical documentation, ensure ongoing conformity, and withdraw non‑compliant goods when required.

Crucially, the CE mark is not a quality seal or proof of third‑party testing—it simply attests to regulatory compliance. When multiple directives apply, they must be addressed and documented transparently. Finally, vigilance against counterfeit CE marks is essential to protect consumers, uphold safety, and preserve trust in the single market.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?