- Continuous or Continual?

- Plan–Do–Check–Act Example

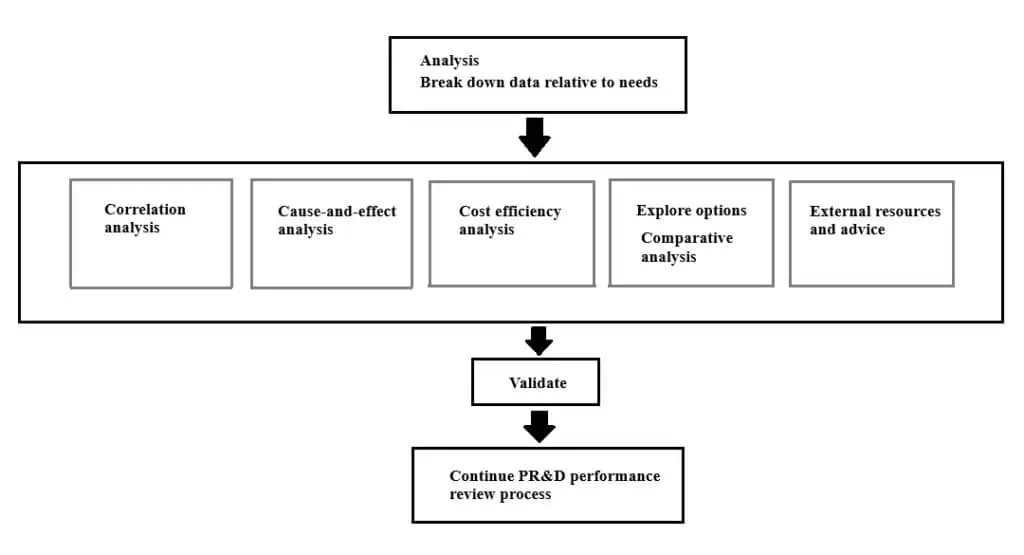

- Pearl River Analysis Process

Continuous Improvement

Among the most widely used tools for continuous improvement is a four-step quality model—the plan-do-check-act (PDCA) cycle, also known as Deming Cycle or Shewhart Cycle:

Plan: Identify an opportunity and plan for change.

Do: Implement the change on a small scale.

Check: Use data to analyze the results of the change and determine whether it made a difference.

Act: If the change was successful, implement it on a wider scale and continuously assess your results. If the change did not work, begin the cycle again.

Other widely used methods of continuous improvement — such as Six Sigma, Lean, and Total Quality Management — emphasize employee involvement and teamwork; measuring and systematizing processes; and reducing variation, defects and cycle times.

Continuous or Continual?

The terms continuous improvement and continual improvement are frequently used interchangeably. But some quality practitioners make the following distinction:

Continual improvement: A broader term preferred by W. Edwards Deming to refer to general processes of improvement and encompassing “discontinuous” improvements—that is, many different approaches, covering different areas.

Continuous improvement: A subset of continual improvement, with a more specific focus on linear, incremental improvement within an existing process.

Some practitioner also associate continuous improvement more closely with techniques of statistical process control.

Plan-Do-Check-Act (PDCA) Cycle

Also called: PDCA, plan–do–study–act (PDSA) cycle, Deming cycle, Shewhart cycle.

The plan–do–check–act cycle is a four– step model for carrying out change. Just as a circle has no end, the PDCA cycle should be repeated again and again for continuous improvement.

When to Use Plan–Do–Check–Act

- As a model for continuous improvement.

- When starting a new improvement project.

- When developing a new or improved design of a process, product or service.

- When defining a repetitive work process.

- When planning data collection and analysis in order to verify and prioritize problems or root causes.

- When implementing any change.

Plan–Do–Check–Act Procedure

- Plan: Recognize an opportunity and plan a change.

- Do: Test the change. Carry out a small scale study.

- Check: Review the test, analyze the results and identify what you’ve learned.

- Act: Take action based on what you learned in the study step: If the change did not work, go through the cycle again with a different plan. If you were successful, incorporate what you learned from the test into wider changes. Use what you learned to plan new improvements, beginning the cycle again.

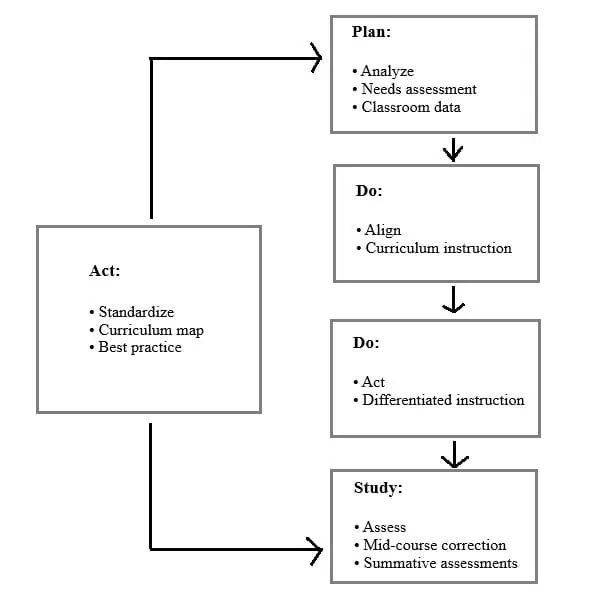

Plan–Do–Check–Act Example

The Pearl River, NY School District, uses the PDCA cycle as a model for defining most of their work processes, from the boardroom to the classroom.

PDCA is the basic structure for the district’s overall strategic planning, needs–analysis, curriculum design and delivery, staff goal – setting and evaluation, provision of student services and support services, and classroom instruction.

The picture shows their “A+ Approach to Classroom Success.” This is a continuous cycle of designing curriculum and delivering classroom instruction. Improvement is not a separate activity: It is built into the work process.

Plan

The A+ Approach begins with a “plan” step called “analyze”. In this step, students’ needs are analyzed by examining a range of data available in Pearl River’s electronic data “warehouse“, from grades of a performance on standardized tests. Data can be analyzed for individual students or stratified by grade, gender or any other subgroup. Because PDCA does not specify how to analyze data, a separate data analysis process (Figure 3) is used here as well as in other processes throughout the organization.

Do

The A+ Approach continues with two “do” steps:

1. “Align” asks what national and state standards require and how they will be assessed. Teaching staff also plans curriculum by looking at what is taught at earlier and later grade levels and in other disciplines to assure a clear continuity of instruction throughout the student’s schooling. Teachers develop individual goals to improve their instruction where the “analyze” step showed any gaps.

2. The second “do” step is, in this example, called “act”. This is where instruction is actually provided, following the curriculum and teaching goals. Within set parameters, teachers vary the delivery of instruction based on each student’s learning rates and styles and varying teaching methods.

Check

The “check” step is called “assess” in this example. Formal and informal assessments take place continually, from daily teacher “dipstick” assessments to every-six-weeks progress reports to annual standardized tests. Teachers also can access comparative data on the electronic database to identify trends. High-need students are monitored by a special child study team.

Throughout the school year, if assessments show students are not learning as expected, mid-course corrections are made such as re instruction, changing teaching methods and more direct teacher mentoring. Assessment data become input for the next step in the cycle.

Act

In this example the “act” step is called “standardize”. When goals are met, the curriculum design and teaching methods are considered standardized. Teachers share best practices in formal and informal settings. Results from this cycle become input for the “analyze” phase of the next A+ cycle.

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

Conclusion

Continuous improvement is not a one-time initiative but an ongoing commitment to refining processes, enhancing quality, and delivering better outcomes. The Plan-Do-Check-Act (PDCA) cycle offers a practical, repeatable framework that embeds improvement directly into daily operations—ensuring that change is purposeful, data-driven, and sustainable. Whether applied in education, manufacturing, or services, PDCA empowers teams to identify needs, test solutions, measure results, and institutionalize success. When supported by robust methodologies like Lean, Six Sigma, and Total Quality Management, and reinforced by a culture of collaboration and accountability, continuous improvement becomes a strategic advantage—driving innovation, performance, and lasting value.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?