- Development of Jidoka

- Concept of Jidoka

- The Evolution and Impact of Jidoka

What Is Jidoka?

Jidoka comes from the Toyota Production system and is very often forgotten even while it is one of the most important principles of lean. Jidoka is about quality at source or built in quality. There is no company which could be competitive without excellent quality of product and service and jidoka is the way how can be this achieved.

Development of Jidoka

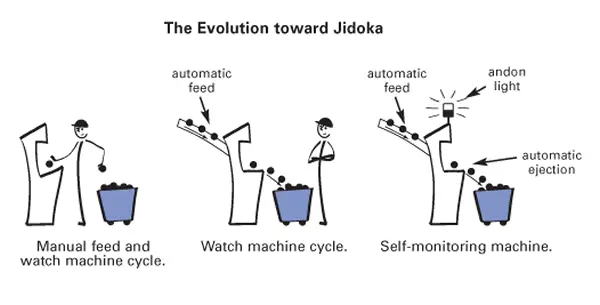

Jidoka was invented by Sakichi Toyoda (Founder of the Toyota Group) in 1896 by a simple device that could stop the shuttle on an automatic loom if the thread broke.

This meant that it prevented the machine from not only creating defects but also warned the operator to a problem. This gave the possibility to one operator to operate several looms and not to stand only at one machine and to watch if something goes wrong. This principle became known as Autonomation or automation with a human touch.

The Toyota term “jido” is applied to a machine with a built-in device for making judgments, whereas the regular Japanese term “jido” (automation) is for a machine that works on its own. Jidoka refers to automation with a human touch, as opposed to a machine that simply moves under the monitoring and supervision of an operator.

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

Principles of Jidoka

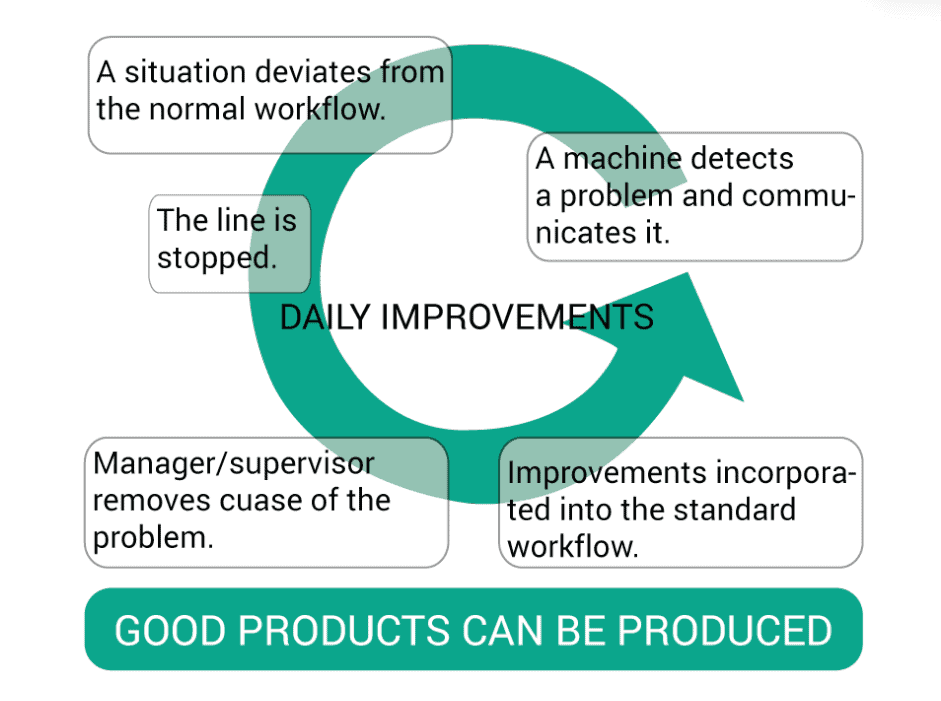

The principle of Jidoka is divided into 4 steps:

- Discover an abnormality

- Stop

- Fix the immediate problem

- Investigate and correct root cause

The benefit of jidoka is its utilization. Is not used only within machines through autonomation, is also visible in almost every aspect of lean manufacturing when you start to examine it. It is about building quality into a process rather than inspecting for it at the end of the process.

The first step of jidoka is to detect the abnormality, so for autonomation the machine uses simple sensors to detect a problem and then stops and highlights the problems for the operator.

For line stop the operator detects an abnormality and stops the line and highlights the problem for all to see on an andon board.

Since the loom stopped when a problem arose, no defective products were produced. This meant that a single operator could be put in charge of numerous looms, resulting in a tremendous improvement in productivity.

Since equipment stops when a problem arises, a single operator can visually check and monitor many machines. As an important tool for this visual control is suitable the problem display board system called andon which is used by Toyota plants. This system allows the operators to identify problems in the production line with only a glance.

Conclusion

Jidoka is a powerful Lean principle that ensures quality is embedded in every step of the production process. By empowering machines and people to detect problems early, stop operations, and resolve root causes, Jidoka prevents defects from accumulating and enables continuous improvement. Far from being just an automation strategy, it represents a culture of responsibility, transparency, and built-in quality. When applied correctly, Jidoka leads to fewer errors, greater efficiency, and stronger customer satisfaction—making it essential for any organization committed to excellence.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?