- Possible Pitfalls of Pushing Zero Defects

- Statements That Do Not Align with Facts

- Sample Size Versus Probability of Failure Graph

Or perhaps it refers to designing defects out of the process or product, so that – theoretically at least – a company can consistently manufacture a defect-free product. There is value in trying to understand the meaning and purpose of this oft-used term, and whether its use is the best approach in a Six Sigma environment of continuous improvement.

Possible Pitfalls of Pushing Zero Defects

Literally zero defects corresponds to a defect level of infinity sigma, which most practitioners will admit is not possible.

And yet an enthusiasitically institutionalized zero defects program may unfortunately promote the belief and expectation that true zero can and should be achieved. This is evidenced by several phhrases that quality professionals may have heard spoken – or at least heavily implied – by business strategists:

“All defects are the same, since all defects are bad…”

“There is no such thing as a benign defect.”

“If we can get rid of the defects, then we can get rid of the testing.”

These expectations are worth examination.

Statements That Do Not Align with Facts

In fact, all defects are not equal. Defects, depending on their size and type, have different probabilities of impacting the finished product. And these probabilities depend on the technology. In fact, the impact probability of a particular defect may vary within the technology – that is, at the stage or layer in which it occurs.

When it comes to the practical definition of a defect, “bad” is a relative term. Many defects are simply neutral. They are never good, but – again, depending on the technology – they may cause no harm either. If all defects are considered bad, then prioritization is difficult.

It is the role of statistically minded scientists and engineers to classify defects and their potential impact, based on data and engineering judgment. This allows them to systematically reduce defect levels in a prioritized fashion, starting with the worst and progressing toward the more benign. Without this kind of problem-solving prioritization, progress may be slow and confused – perhaps even at a standstill. The ability to prioritize is absolutely necessary in the continuous improvement process.

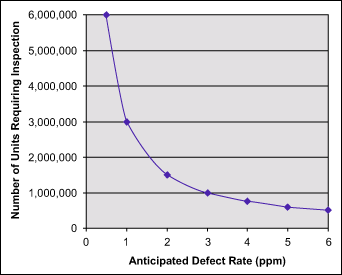

The statement that if fewer defects are produced, then less inspection will be required is incorrect. Actually, the opposite is true. A higher level and sophistication of testing is required to detect a smaller level of defects. The plot in picture, derived from a cumulative binomial distribution (pass/fail inspection) shows how the sample size increases exponentially as the prevalence of a defective unit decreases. The particular curve in Figure 1 corresponds to a probability of detection of 95 percent. In other words, if a defect is present at the indicated level (x-axis), there is a 95 percent probability that at least one failed unit will be detected using the sample size indicated on the y-axis.

Ideally suppliers need to produce the highest quality output possible, in order to maximize yield and minimize costs which ultimately benefits both the supplier and the customer. But a zero defects policy does not provide this motivation to suppliers. When the goal of zero defects is applied to multiple interim points along the supply chain, the undesired effects of increased costs and lower yields are encouraged.

The increased costs come from increased tests, inspections and cycle time. The lower yields are likely because of a higher rate of “false fails” (type 1 errors) as the suppliers apply increasingly stringent criteria in an attempt to eliminate potential failures at the customer’s incoming test/inspection. In other words, in an effort to eliminate even the smallest possibility of customer incoming test failures, good product may be scrapped to overly stringent criteria.

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

The Pros and Cons of Zero Defects

Zero Defects is based on four key principles:

- Quality is simply conformance to requirements, not some sort of measure of performance or goodness

- It is always cheaper to do the job right the first time than to correct problems later (quality should be ensured through prevention, not appraisal)

- Quality is measured in monetary terms (the price of non-conformance)

- The performance standard must be Zero Defects, not “that’s good enough”.

The key word for achieving Zero Defects is prevention, you don’t get ZD by simply taking corrective actions to rectify existing problems, you have to stop them occurring in the first place.

The Case for Zero Defects

Zero Defects addresses the apathy that you often come across: “There will always be errors, there’s nothing you can do to prevent them”; why do we accept this statement for product manufacturing or software design but wouldn’t accept it from our surgeon as we entered the operating theatre, or in our bank accounts?

Crosby explains that defects represent a cost that is often hidden (inspection, waste/scrap, rework, lost customers, etc). By eliminating defects these costs are sufficiently reduced that the savings more than pay for the quality improvement programme.

The Case Against Zero Defects

Zero Defects is controversial because it’s so difficult to achieve; some people claim it’s ridiculous and counter productive to have a target of zero that will rarely be attained. They believe it will lead to excessive inspection costs and demoralised staff who keep failing.

If implemented without sufficient thought it could even cause defects because of the extra stages of increasingly rigorous and expensive inspection and handling of the products.

Adopting Zero Defects

There are no step-by-step instructions for achieving zero defects, and there is no magic combination of elements that will result in them. There are, however, some guidelines and techniques to use when you decide you are ready to embrace the zero defects concept.

Management must commit to zero defects. Zero defects requires a top down approach: The best-intentioned employees cannot provide zero defects if they are not given the tools to do so.

- When you decide that zero defects is the approach you want to take, recognize that it likely represents a significant change to the way people do things. Manage the introduction using the principles of change management.

- Understand what your customers expect in terms of quality. Design systems that support zero defects where it matters, but don’t over-design if the end-user just doesn’t care.

- Zero defects requires a proactive approach. If you wait for flaws to emerge you are too late.

- Create quality improvement teams. Zero defects must be integrated with the corporate culture. Zero defects needs to be accepted as “the ways things are done around here”.

- Learn poka-yoke. Invented in the 1960s by Shigeo Shingo of Japan, it translates to “prevent inadvertent mistakes”. It’s an approach that emphasizes designing systems that make defects almost impossible or, if they can’t be avoided, easy to detect and address. To implement zero defects, you have to have strong systems in place.

- Monitor your progress. Build mechanisms into your systems and methods of operating that provide continuous feedback. This allows you act quickly when flaws do occur.

- Measure your quality efforts. It is important to express your progress in terms of the bottom line. Take baseline measurements so you understand the cost of defects in your organization, and can measure the benefits your achieveing in eliminating them.

- Build quality into your performance expectations. Encourage members of your team to think about how they can achieve zero defects, and reward them when they’re successful.

- Recognize that although zero defects is a destination, circumstances keep changing. Monitor, evaluate, and adapt in a continuous, never-ending cycle.

Conclusion

Zero Defects is best seen not as a literal goal, but as a mindset focused on prevention, continuous improvement, and doing things right the first time. While aiming for perfection can drive better quality, unrealistic expectations may lead to higher costs, unnecessary inspections, and frustration. When applied thoughtfully—with strong leadership, clear priorities, and practical systems—Zero Defects can support meaningful progress without compromising efficiency or morale.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?