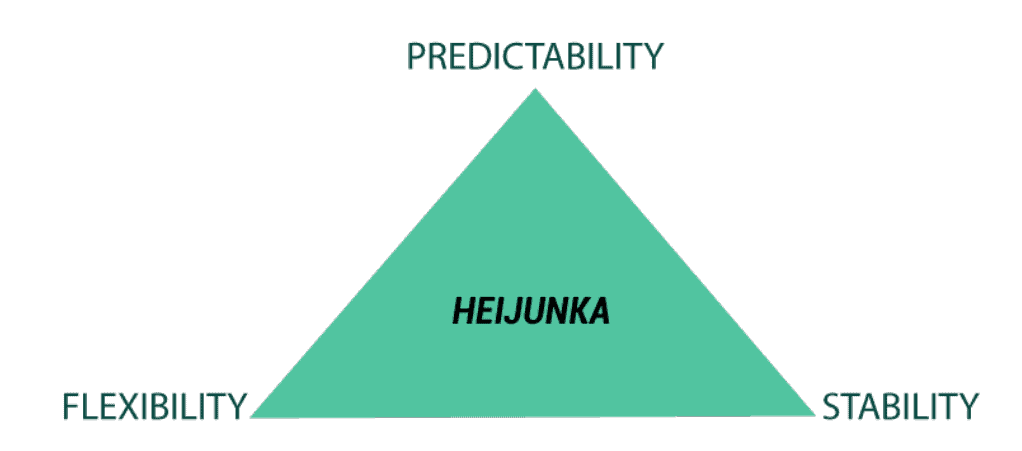

- Relationship Among Predictability, Flexibility and Stability

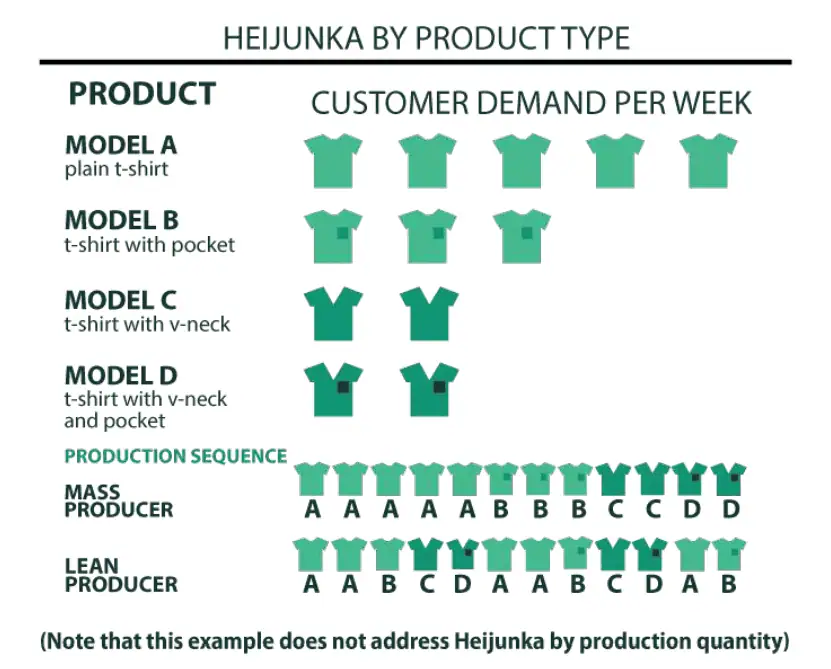

- An Example of Heijunka in Process

- Example of Leveling Production by Type of Item

What Is Heijunka?

Definition of heijunka by Lean Lexicon: Leveling the type and quantity of production over a fixed period of time. This enables production to efficiently meet customer demands while avoiding batching and results in minimum inventories, capital costs, manpower, and production lead time through the whole value stream.

An Example of Heijunka in Process

Leveling the type and quantity of production enables production to efficiently meet customer demands while avoiding batching and results in minimum inventories, capital costs, manpower and production lead time through the whole value stream. With regard to level production by quantity of items, suppose that a producer routinely received orders for 1000 items per week, but with significant variation by day: 400 items arrive on Monday, 200 on Tuesday, 100 on Wednesday, 200 on Thursday and 100 on Friday.

To level production, the producer might place a small buffer of finished goods to cover the demands and level production at 200 units per day through the week. By having a small stock of finished goods at the very end of the value stream, producer can organize demand to its plant and to its suppliers, making for more efficient utilization of assets along the entire value stream while meeting customer requirements.

On the picture you can see that a shirt company offers Models A, B, C, and D to the public and that weekly demand for shirts is five of Model A, three of Model B, and two each of Models C and D. A mass producer, seeking economies of scale and wishing to minimize changeovers between products, would probably make the shirts in the weekly sequence A A A A A B B B C C D D.

A lean producer, would try to build in the repeating sequence A A B C D A A B C D A B (infrequent batches of orders upstream to suppliers), making appropriate production system improvements, such as reducing changeover times. This sequence would be adjusted periodically according to changing customer orders.

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

Implementation of Heijunka

To have the right direction for company assure these core concepts about heijunka.

- Takt time: The time it takes to finish a product in order to meet customer demand.

- Volume leveling: Production at levels of long-term average demand and keep a buffer inventory proportional to variability in demand.

- Type leveling: Make every product every day and reserve capacity for changeover flexibility.

- Heijunkabox: A working diagram of type leveling and production schedule.

- Work slowly and consistently

- Changeover time: decreasing the changeover times helps tighten the value stream between supply and demand.

- Buffer inventory: Having some product ready to ship at the beginning of each production cycle is essential to smoothing production and leveling demand at consistent rates and quality so that resource waste is minimized on the line.

- Type standardization: By manufacturing one of each product or service a day, knowledge can be more readily shared across types to benefit every process.

Conclusion

Heijunka is a foundational concept in Lean production that enables organizations to meet customer demand efficiently—without overproduction, excessive inventory, or wasted resources. By leveling both the type and quantity of production, businesses can create a smooth and consistent workflow that aligns with takt time and minimizes disruptions caused by fluctuating orders.

Through tools like the Heijunka box, volume and type leveling, and reduced changeover times, companies can optimize the entire value stream. Implementing Heijunka leads to better asset utilization, higher quality, and more responsive production systems—turning variability into stability and chaos into control.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?