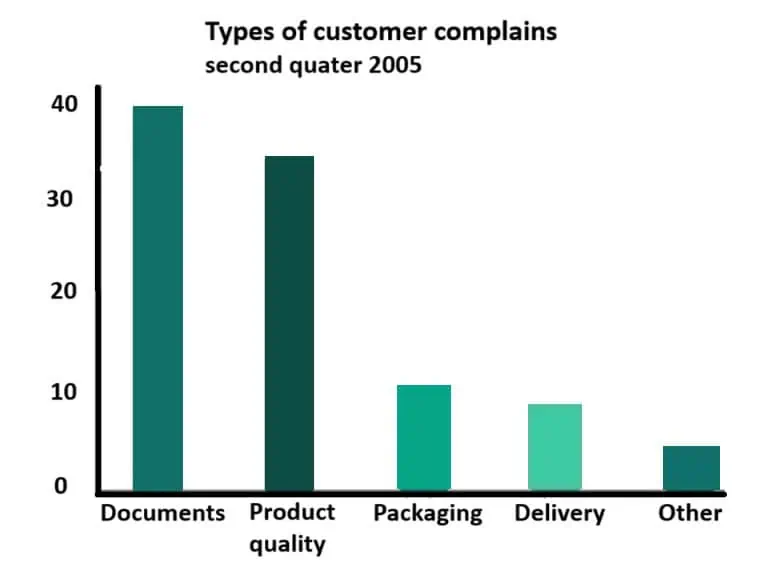

- Example of Pareto Diagram

- When to Use It?

- How to Use It?

- What Is Pugh Analysis?

What Is Pareto Chart?

A Pareto diagram is a bar graph. The lengths of the each bar mean the frequency or cost (time or money) and are placed with longest bars on the left and the shortest to the right. In this way the chart visually shows which situations are more significant. The 80-20 theory was first developed in 1906, by Italian economist, Vilfredo Pareto, who observed an unequal distribution of wealth and power in a relatively small proportion of the total population. The business applications were adapted by Joseph M. Juran.

Why Is It Important?

Pareto chart is a tool for visualising the Pareto principle, which states that a small set of problems can affect much more a common outcome tend than the remaining items. A Pareto chart can be used to decide which subset of problems should be solved as first ones, or which problems need the most attention. Pareto charts are often constructed to provide a before-and-after comparison of the effect of control or quality improvement measures.

When to Use It?

The Pareto Chart is used to demonstrate the occurrences of problems or defects in a descending order. It is used for making decisions at critical points in different processes, which means it can be used both during the development phase as well as when products are in serial use, e.g. customer complaints.

- When analyzing data about the frequency of problems or causes in a process.

- When there are many problems or causes and you want to focus on the most significant.

- When analyzing broad causes by looking at their specific components.

- When communicating with others about your data.

How to Use It?

Step by step process to address an issue:

- List all elements of your interest.

- Measure the elements, for measurement use the same unit for each element.

- Order the elements according to measurement results.

- Calculate the percentage for each element out of the total measurement.

- Accumulate the percentage from top to bottom to equal 100%.

- Create a bar and line graph, line represents the cumulative percentage.

- Work on the most important element (or elements) first.

Pareto charts are a key improvement tool because they help us identify patterns and potential causes of a problem. One trick which is often overlooked is to create several Pareto charts out of the same set of data. More Pareto charts can help quickly scan a number of factors that might contribute to a problem and focus on those with the greatest potential risk.

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

What Is Pugh Analysis?

Pugh Analysis is very similar to the pros vs. cons lists. These charts are used for evaluation of multiple options, factors, indicators against each other, in relation to a main baseline option. The Pugh matrix helps determine which items or potential solutions are more important or ‘better’ than others. The method was created by Stuart Pugh from Scotland as an approach for selection of concept alternatives.

Why Is It Important?

This chart is great for use due to time needed for creation. To create the chart takes a development team to analyze the scores and weighting factors is usually much shorter and cheaper compared to deploying the wrong solution to a project. The next step ranking the criteria further helps focus the team’s efforts on the critical few.

The Pugh matrix allows an individual or team to:

- Compare different concepts.

- Create strong alternative concepts from weaker concepts.

- Create an optimal concept that may be a combination or variant of the best of other concepts.

When to Use It?

To list the positive and negative aspects of each option, one by one, to create a matrix of the needs vs. concepts helps address multiple factors at the same time and gives the team a holistic view of the needs vs. alternatives at hand.

How to Use It?

Step by step process:

- Develop a set of criteria according to the customer’s requirements.

- Enhance these criteria by including any item of functional nature.

- Generate a group of design concepts which are meant to satisfy the criteria.

- Using a simple matrix – list criteria on the left and the concepts across the top. Use simple sketches to illustrate each of these concepts.

- Set one of the concepts as a baseline.

- Evaluate each concept against the datum for each of the criteria. Determine whether it is better (+), the same (0) or worse(-) than the baseline. Alternately, one could assign a -1, 0, +1 based on where each choice would stack up against a set of the agreed-to criteria. We could give each of these criterion a weight and get the composite score of the alternate criterion to determine the better alternative.

- Record the team’s decisions on the matrix.

- For each column, determine the total number of pluses, minuses and sames. Alternately, take the sum of the alternate score multiplied by weight of the criterion.

- Work to improve those concepts that scored best by incorporating strong ideas from other concepts.

- Continue the process of synthesizing concepts.

Conclusion

The Pareto chart in quality control is more than just a bar graph—it’s a strategic tool that empowers organizations to tackle the most critical issues with clarity and purpose. By separating the “vital few” from the “trivial many,” teams can allocate time, resources, and attention where they will have the greatest impact.

Whether used to analyze defects, reduce downtime, or improve customer satisfaction, the Pareto chart drives data-informed decisions that lead to measurable results. When embedded into regular quality control practices, it supports a culture of continuous improvement and proactive problem-solving that enhances both operational efficiency and long-term business performance.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?