- Mistakes vs Defects

- Quality Control vs Poka Yoke

- Example of Poka Yoke

What Is Poka Yoke?

Poka yoke (also called mistake proofing or fail–safing) is a simple technique used with jidoka. It is the use of any automatic device or method that prevents defects from being made or highlights a defect so that it is not passed to the next operation. Whether it’s a warning light or a mechanism that physically blocks incorrect actions, Poka Yoke ensures that problems are detected and corrected at the source—protecting both the production process and the end customer.

The Development of Poka Yoke

Poka yoke was created by Shigeo Shingo who wrote the definitive works on this technique, but originally he is not the one who invented the idea of mistake proofing.

At the beginning the technique was called by many people as fool-proofing (baka yoke), but due to dishonorable and offensive meaning it was changed to poka yoke.

Mistakes vs Defects

He differentiates between mistakes which in most cases are inevitable and defects which are mistakes that manage to get through the system and reach the customer. Poka yoke seeks to prevent mistakes from becoming defects.

Quality Control vs Poka Yoke

Shigeo Shingo saw quality control as a three level hierarchy of effectiveness:

- Judgement inspection – inspectors inspect

- Informative inspection – use of SPC to monitor the process conditions

- Before the fact – poka yoke

Download our e-book

Download our free e-book to discover how GQ Interim can transform your business with expert leadership solutions!

Purpose of Poka Yoke

To overcome the inefficiencies of inspection is able through the use of automatic devices which seek to do three things:

- Not accept a defect for the process

- Not create a defect

- Not allow a defect to be passed to the next process.

They do this in a number of different ways but can be categorized as being either:

- Control – they take physical action to prevent a defect

- Warning – They sound an alarm or light up to tell us a mistake has been made.

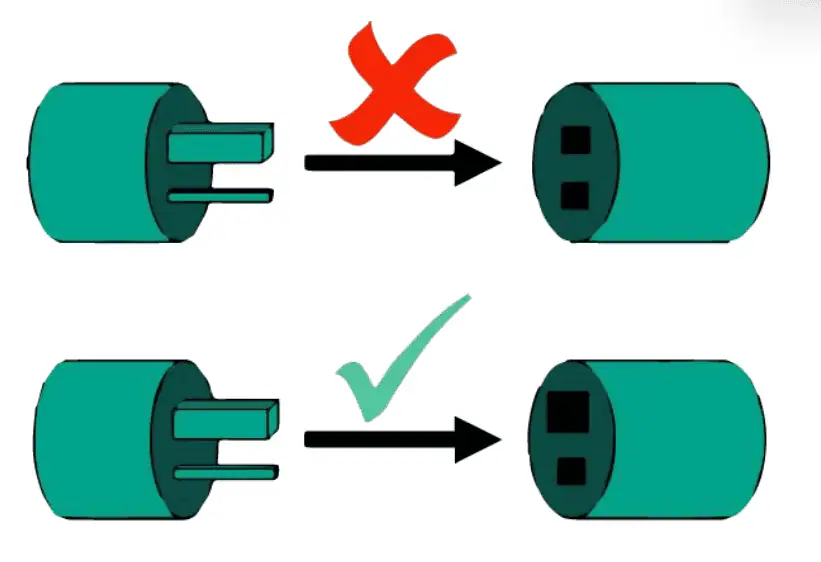

An example or a control type Poka Yoke is one that physically rejects an defected product on a conveyor whilst a warning. Poka yoke is one that sounds an alarm.

They can be further classified into the following three types:

- Contact – for example devices that have physical shapes that are used to prevent the use of incorrect components

- Fixed value – method that uses physical and visual methods to highlight that all components are available in the right quantities and have been used, sometimes combined with contact style sensors to make them more positive.

- Motion stop – it is ensured the correct number of steps have been taken and possibly also the sequence of steps for example if the correct torque is not reached or if the operator does not tighten all of the bolts the part will not be released to the next operation.

Poka Yoke is one of the most effective ways to prevent defects reaching your customers and should be used in any lean manufacturing or Total productive maintenance (TPM) implementation.

Conclusion

Poka Yoke is a fundamental technique in Lean manufacturing that transforms quality control from reactive inspection into proactive prevention. By using simple, effective methods to catch errors before they become defects, Poka Yoke reduces waste, boosts efficiency, and safeguards customer satisfaction. Whether through physical controls or visual warnings, it empowers teams to build quality directly into the process. As part of any robust Lean or TPM strategy, implementing Poka Yoke not only minimizes risk but also fosters a culture of accountability and continuous improvement.

Interested in Interim Expert?

Discover how interim management can dramatically increase the efficiency of your business. Get in touch with our team to learn how working with GQ Interim will improve your company.

- Get started within few days

- Database of 10 000+ consultants

- Solving crucial problems of your business

- Custom solutions for your business needs

- Proven results with measurable impact

Related articles

- A balanced scorecard example demonstrates how organizations can measure more than just financial performance. Developed by Robert Kaplan and David Norton, the balanced scorecard tracks goals across finance, customers, internal processes, and learning & growth. By aligning these perspectives, it ensures that daily operations support long-term strategy and sustainable growth.

- The Theory of Constraints (TOC) is a structured approach to improving organizational performance by focusing on the single most limiting factor—the constraint. Whether it’s a production bottleneck, market demand, or a sales conversion gap, TOC answers three core questions—what to change, to what to change, and how to cause the change—and drives continuous improvement through five disciplined steps: identify, exploit, subordinate, elevate, and repeat.

- Software quality assurance ensures that software consistently meets stakeholder needs by preventing defects and validating that products align with defined quality attributes (e.g., reliability, security, performance). Blending defect management practices with standards-based quality models like ISO/IEC 25010 helps teams plan, measure, and continuously improve quality throughout the lifecycle.

- During our jobs we meet very often with many symbols and shortcuts or abbreviations e.g. FMEA, PPAP, CC, SC etc. When I did my first internal audit at work I had to also check the implementation of CE marking. Previously I have done the research what is this CE marking to not be absolutely lost in this area. So what is it and how is itused?